Recycled asphalt repair in Colorado offers a cost-effective and eco-friendly solution for maintaining commercial parking lots and roads. In Denver and Aurora, harsh weather conditions like freeze-thaw cycles, intense UV exposure, and heavy snow accelerate pavement wear, making durable repairs essential.

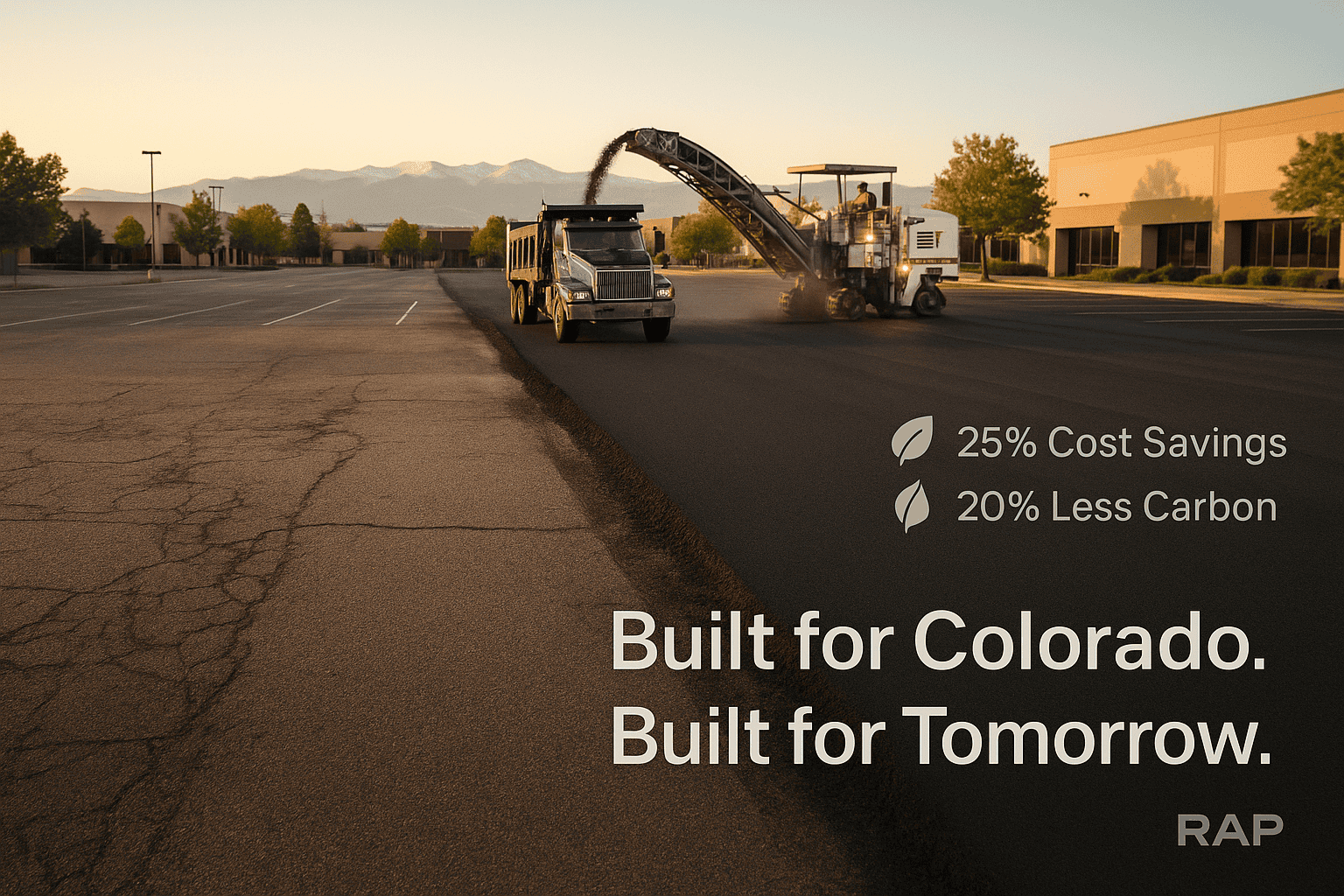

According to a 2021 study, RAP can cut material costs by up to 25% and carbon emissions by 20% or more, making it ideal for businesses aiming to balance budgets and sustainability goals. At Asphalt Coatings Company, our services ensure compliance with local regulations, enhancing safety and longevity for your property.

The Science Behind Reclaimed Asphalt Pavement (RAP)

What RAP Is & How It’s Made

Reclaimed asphalt pavement (RAP) consists of recycled asphalt material sourced from old pavements. RAP is produced by milling worn asphalt surfaces, crushing and screening the material to achieve uniform gradation, and blending it with new asphalt binder and aggregates. This process reduces the demand for virgin materials, lowering costs and environmental impact. The Federal Highway Administration notes that RAP is America’s most recycled material, with approximately 73 million tons reused annually. At Asphalt Coatings Company, we manage this process in-house, ensuring high-quality RAP for Denver-area projects.

RAP vs. Virgin Mix Performance Metrics

RAP performs comparably to virgin asphalt mixes when properly designed. Studies from the National Center for Asphalt Technology (NCAT) show that RAP mixes with up to 15% content require no binder grade adjustments, maintaining flexibility and durability. For higher RAP percentages, a softer virgin binder can offset increased stiffness, reducing risks of cracking in cold climates like Colorado. NCAT’s test track data indicates that a 45% RAP mix exhibited only 0.5 mm of rutting after 9 million equivalent single axle loads (ESALs), compared to 8.6 mm for a 20% RAP mix, showcasing superior rutting resistance.

Cost & Carbon Savings You Can Measure

Life-Cycle Cost Analysis for Parking Lots

RAP reduces material costs significantly, offering savings of $6 to $11 per ton for typical mixes with 20% RAP, according to industry reports. For a 5,000-ton parking lot project, this translates to potential savings of $30,000 to $55,000. A 2019 study found that 40% RAP mixes can lower life-cycle costs by 20%, with 100% RAP mixes achieving up to 74% savings. Our clients benefit from these savings without compromising pavement quality, as we tailor mixes to meet Colorado’s rigorous standards.

Carbon Footprint Reductions Documented in LCAs

RAP lowers carbon emissions by reducing the need for virgin asphalt and aggregates. A 2021 life-cycle assessment (LCA) estimated that a 93% RAP mix produced at 105°C can reduce carbon footprint by 55% to 64% compared to virgin mixes at 175°C. In Colorado, where sustainability is a priority, using RAP aligns with state initiatives like the 2021 greenhouse gas transparency law, which encourages low-carbon construction practices. Asphalt Coatings Company’s RAP processes contribute to these environmental goals, helping clients achieve greener projects.

Colorado-Specific Stressors: Freeze-Thaw, UV & Heavy Snow

Why RAP Mixes Handle Thermal Cracking Better

Colorado’s freeze-thaw cycles—averaging 38 per year in Denver—cause water to expand in pavement cracks, leading to potholes and structural damage. RAP mixes, with lower moisture retention due to aged binder, are less susceptible to freeze-thaw damage, as noted in a 2014 study. Our team designs RAP mixes with softer virgin binders to balance stiffness, ensuring resistance to thermal cracking in Denver’s variable climate.

CDOT & City Permitting for RAP Jobs

CDOT allows RAP in asphalt mixes, typically up to 20% for surface courses, as per the 2023 Standard Specifications, ensuring compliance with performance standards. In Denver, the Department of Transportation and Infrastructure (DOTI) requires permits for paving projects, adhering to specifications like those in the city’s asphalt pavement standards. We navigate these regulations seamlessly, ensuring your project meets all requirements near landmarks like Denver’s Union Station.

Comparing Repair Methods: Overlay, Mill-&-Fill, CIR

When to Choose Each Method

- Overlay: Ideal for pavements with minor surface distresses but sound structural integrity. It’s cost-effective and quick, extending pavement life without extensive reconstruction.

- Mill-and-Fill: Best for pavements with significant surface damage, like cracking or rutting, but intact base layers. Milling removes the damaged surface, and new asphalt restores smoothness.

- Cold In-Place Recycling (CIR): Suited for deeper rehabilitation, reusing existing materials for sustainability. It’s ideal for pavements with fatigue cracking or structural issues.

Typical Timelines & Traffic Control

| Method | Timeline | Traffic Control |

| Overlay | 1–2 days | Lane closures during paving |

| Mill-and-Fill | 2–4 days | Road closure during milling and paving |

| CIR | 3–7 days | Extended closure for recycling process |

Each method requires careful traffic management to ensure safety. Asphalt Coatings Company minimizes disruptions, coordinating with local authorities near areas like Cherry Creek Shopping Center.

Compliance & Liability Considerations

ADA Slopes, Trip Hazards, and Striping Updates

ADA-compliant slopes are critical for accessibility, with curb ramps requiring a maximum slope of 1:12 (8.33%) per the 2010 ADA Standards. Trip hazards, such as uneven pavement, must be addressed to prevent accidents and lawsuits. After repairs, we update striping to meet Denver’s safety and regulatory standards, ensuring clear lane markings and ADA-compliant parking spaces.

Stormwater & MS4 Requirements

Denver’s stormwater regulations mandate managing runoff to prevent pollution, as outlined in the city’s Stormwater Ordinance. Our RAP projects incorporate proper drainage designs, complying with Municipal Separate Storm Sewer System (MS4) requirements to protect local watersheds like the South Platte River.

Step-by-Step: Asphalt Coatings Company RAP Process

In-House Milling & Stockpile Management

We mill asphalt in-house, using advanced equipment to collect RAP efficiently. Our stockpiles are carefully managed, with RAP fractionated into coarse and fine sizes for precise mix design. This ensures consistency and quality, tailored to Colorado’s climate challenges.

Quality-Control Testing & JMF Approval

Our quality control involves rigorous testing of RAP properties and developing a Job Mix Formula (JMF) that specifies RAP, virgin aggregates, and binder proportions. We ensure compliance with CDOT standards, guaranteeing durable pavements that withstand Denver’s weather.

Budgeting & Financing Your Project

Sample Bid Breakdown

A typical RAP-based repair bid includes:

- Mobilization: Equipment setup and site preparation.

- Milling: Removing damaged asphalt ($2–$3/ton).

- RAP Processing: Crushing and screening ($1–$2/ton).

- Paving: Applying the RAP mix.

- Striping: Updating markings for safety and compliance.

Using RAP reduces material costs, saving up to 25% compared to virgin mixes.

Grants & Green-Building Incentives

Colorado offers incentives for sustainable construction, such as the Colorado Clean Energy Fund’s loans for eco-friendly projects. Using RAP may qualify for federal tax credits or local rebates, as it reduces carbon emissions. Contact us to explore eligibility for your project.

FAQs About Recycled Asphalt Repairs

- Does recycled asphalt last as long as new asphalt?

Yes, properly designed RAP mixes meet the same performance grades as virgin mixes, often resisting cracking better in cold climates. - Is RAP approved by Colorado DOT?

CDOT permits up to 20% RAP in surface courses, with higher percentages in base layers, subject to quality control. - Will my lot look as dark as fresh asphalt?

RAP mixes may appear slightly lighter initially, but sealcoating restores a uniform dark finish.

Get Your Denver-Area Quote Today

Schedule your free on-site RAP audit with Asphalt Coatings Company today. Our Denver-based crew delivers cost-effective, sustainable repairs that withstand Colorado’s climate. Contact us at Asphalt Coatings Company to lock in pre-winter pricing and ensure your parking lot is ready for the season.